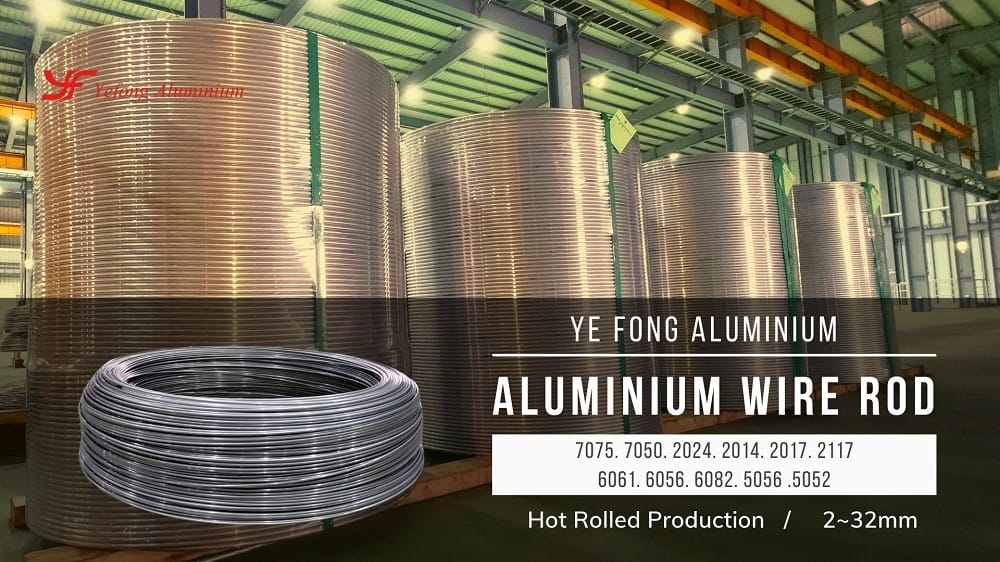

Aluminum Alloy Wire Rod-Hot Rolled Production by Ye Fong Aluminium

With our special hot-rolling technology we can process a wide range of sizes and alloys, delivering fine-grained structures with excellent formability. The main end-use markets are aerospace, automotive, and general engineering industries fasteners in aluminum alloy 7075. 7050. 2024. 2011 .2014. 2117. 4032. 6061. 6056. 6082. 5056 . 5052..etc. The applicable aluminum fastener includes Rivet, Rivet Nut, Screws, Bolt, Stud, Washer, Pin, Bushing, Nails, Clips, Staples…etc. Our hot roll aluminum rod offers a consistent quality product for customers’ needs. Ye Fong Aluminium team will work with you closely to deliver products to your specifications for your specific application.

Aluminum REDRAW ROD (Hot Rolled) | ||

Diameter | Tolerance | Weight per coil |

32mm (1.259”) | +/- 0.3mm | 250 KG (550 LB) |

28mm (1.102”) | ||

25mm (0.984”) | ||

22mm (0.866”) | ||

20mm (0.787”) | ||

16mm (0.630”) | ||

13mm (0.512”) | ||

11mm (0.433”) | ||

8mm (0.315”) | ||

** For diameter larger than 32mm available thru inquiry. | ||

Aluminum FINISHED WIRE (Hot Rolled) | ||

Diameter | Tolerance | Weight per coil |

2mm - 30mm | +/- 0.03mm | 250KG (550LB) |

PACKING METHODS | ||

Loose Coil / Tight Coil (Spool) | ||

ALUMINIUM ALLOY REDRAW ROD

- Diameter: 8, 11, 13, 16, 20, 22, 25 , 28, 32mm (0.315″, 0.433″, 0.512″, 0.630″, 0.787″, 0.866″, 0.984″ , 1.102″, 1.259″)

- Weight: 250 kg (550 lb)/coil ( no welding )

- Roundness 0.3mm(0.012″)

- Alloys: 7075. 7050. 2024. 2011. 2014. 2117. 4032. 6061. 6056. 6082. 5056. 5052 …etc. ( All alloys, mainly focus on high strength alloys)

- Tempers: F/O

- Applications: Forging/ Drawing

ALUMINIUM ALLOY FINISHED WIRE

- Diameter : 2mm – 30mm (0.08″ – 1.181″)

- Weight: Max. 250 kg (550 lb)/coil ( no welding )

- Roundness 0.02mm(0.00008″)

- Alloys:7075. 7050. 2024. 2011. 2014. 2117. 4032. 6061. 6056. 6082. 5056. 5052.etc. ( All alloys, mainly focus on high strength alloys)

- Tempers: O /H /T

- Applications: Cold heading fasteners such as rivet, rivet nut, screws, bolt, bushing, stud, washer, pin….etc.

ADVANTAGE

Superior in surface quality, formability, machinability, better quality. Homogenization Treated & Inspected by Ultrasonic & Segregation Layer Removed & On-line Eddy Current Inspection

ADVANTAGE

The fastener which is produced in hot rolled wire could be applied in aerospace application; However, the fastener which is produced by traditional continuous casting wire only could be applied in other applications such as automotive and industrial, they cannot be used in aerospace application since they cannot guarantee the purity of material (segregation layer) and lead to insufficient strength.

ADVANTAGE

YE FONG produces hot rolled redrawn rod and finished wire by ourselves at the same time, not like other mill need to outsource the redrawn rod. Therefore, the quality & cost could be controlled by ourselves.

ADVANTAGE

Only manufacturer who carry both HOT ROLLED WIRE and WIRE SHAVING in house

EXCLUSIVE TECHNOLOGY TO MANUFACTURE HOT ROLLED WIRE FOR AEROSPACE FASTENERS

- Ye Fong now specifically supplies aluminum alloy materials for aerospace screws, nuts, small rivets and other fasteners in various diameters. This type of material is in short supply due to the scarcity of its makers. Rivets are made of hot rolled wires and currently only few companies in the world can manufacture those wires made of high-strength aluminum alloy. One of them can only provide 200kg per coil. The other, which is Ye Fong, has come up with an exclusive technology to be the world’s first supplier to provide 300kg per coil.

EXPERT OF AEROSPACE FASTENER MATERIALS

- Aerospace fasteners are made of hot-rolled aluminium alloy wire rods. A Boeing 747 aircraft users more than 2 million fasteners and therefore needs a large amount of material. The wires Ye Fong produces for fasteners ranging from 2mm up to 32mm can cover all the usage demand for fasteners. These wires per coil weight 300kg without welding, which is an exclusive advantage to Ye Fong. It indeed saves a lot of cost for customers on time-changing and labor cost..

- Aerospace fasteners are mostly made of wire rods and sometimes straight bars. Wire rods are mostly made by continuous high speed forging and therefore reduce cost. On the other hand, straight bars are made by CNC processing and therefore its production is slower. To be accepted into the aerospace market, wire rods must be in a flawless state by shaving the surface of the aluminum wires as an additional process. It is very easy to peel titanium, steel and copper wires, but shaving aluminum alloy is extremely difficult. After a year of research and improvement, we are finally develop the technology to shave aluminum alloy successfully.

COMPARISON TO CAST-ROLLING (CONTINUOUS CASTING) WIRE ROD

- The aluminum wire from Ye Fong is hot-rolled type instead of a cast-rolled type. The highest application of fasteners manufactured by cast-rolling can only be used for automotive, and cannot be used for aerospace. However, the aluminum wire produced by hot-rolled method completely solves the problem of surface segregation layer impurities and non-uniformity grain structure. This is achieved through Ye Fong peeling, shaving, hot rolling, homogenization treatment, on-line eddy

current test and other manufacturing processes. It also provides fastener manufacturers with better machinability & formability, meeting the demand of the aerospace and automotive fastener markets at the same time.

THE FUTURE TREND OF FASTENER MARKET

Lightweight design of aerospace fasteners

Corresponding to the trend of energy saving, carbon emissions reduction, and consolidating the competitiveness of airline companies, Lightweight aircraft design has become the ainstream trend in the aviation industry, and the fastener is definitely one of the main items of lightweight design. In addition to lightweight design, the strength of the fastener itself must conform to aeronautical safety standards as well. Therefore, the demand for lightweight designs in high-strength aluminum fasteners is about to see a boom in the future.

Application of automotive fasteners

Nowadays, it’s an inevitable trend to reduce the weight of vehicles. Not only the frame, body sheet metal, and chassis are all developing toward lightweight designs, but also the high-end models are aluminum alloyed for engines and transmissions. Therefore, expanding the aluminum fastener market is also the mainstream trend at this moment for the automotive market.